Owning a motorcycle, whether you ride a city commuter, an adventure tourer, or a heavy cruiser, eventually leads to a question every rider faces: What’s under the rear wheel? That question centers on your motorcycle drive transmission type: chain, belt, or shaft. Each has distinct advantages, drawbacks, and maintenance needs. Choosing the right one and knowing how to maintain it can make the difference between smooth rides and costly breakdowns.

If you’re new to bikes or want to understand your motorcycle drive transmission better, this guide breaks down everything: how each drive system works, pros and cons, maintenance tips, to get you started right.

Chain, Belt, or Shaft, What’s the Difference?

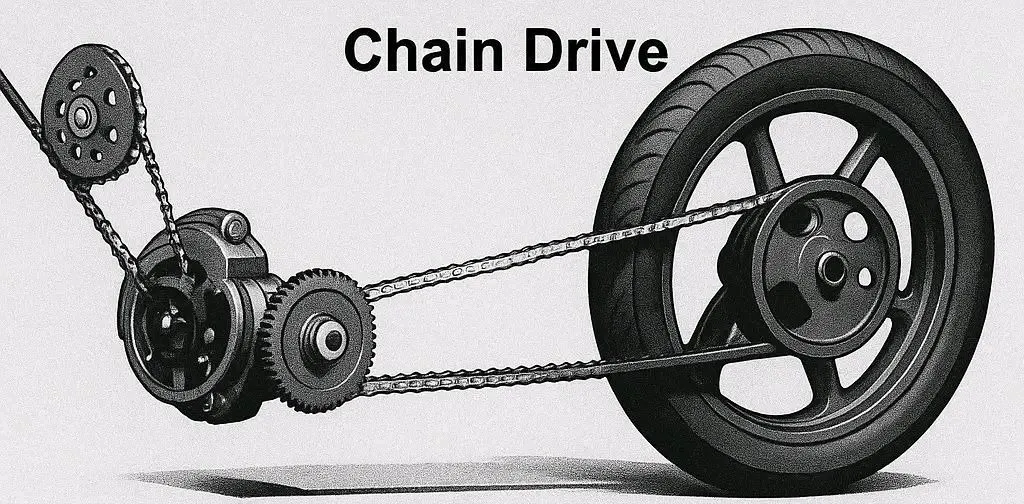

Chain Drive

The most common setup, especially on sportbikes, versatile street bikes, and many adventure/touring machines. A steel chain connects the engine’s final drive sprocket to the rear wheel sprocket. Simple, cost-effective, and easy to modify.

Why riders like it:

- high power transfer efficiency

- low cost of maintenance/repairs

- easy to change sprocket ratios for performance tuning or fuel economy

Maintenance needed:

- periodic cleaning and lubrication

- tension adjustment

- sprocket & chain replacement when wear appears

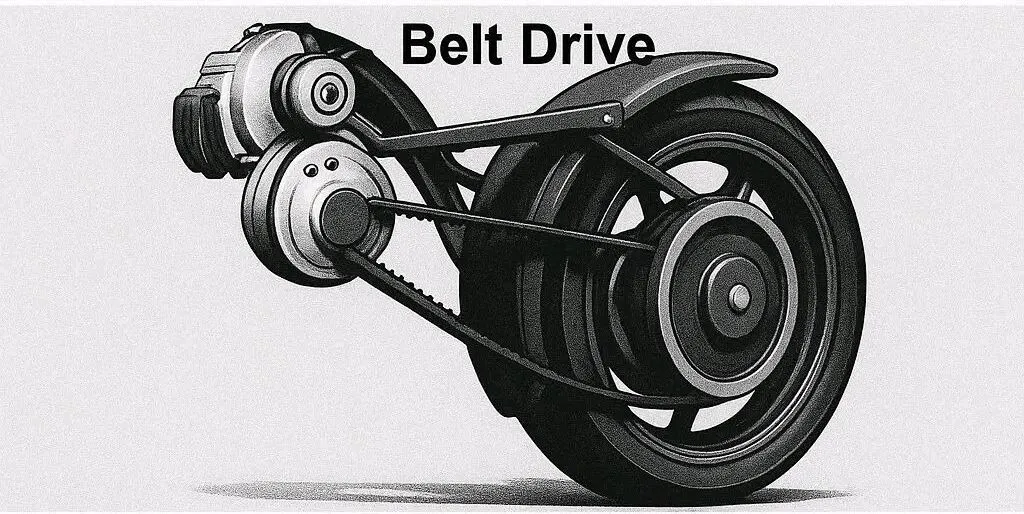

Belt Drive

Instead of metal links, a reinforced rubber belt (with cords) transfers power, using belt pulleys instead of sprockets. Popular with cruisers and some touring motorcycles due to smooth, low-maintenance operation.

Why riders like it:

- quiet, vibration-free ride

- minimal maintenance required (no lubrication!)

- long belt life under normal riding

Maintenance needed:

- belt inspection for cracks, wear, or stretch

- correct belt tension checks

- pulley alignment

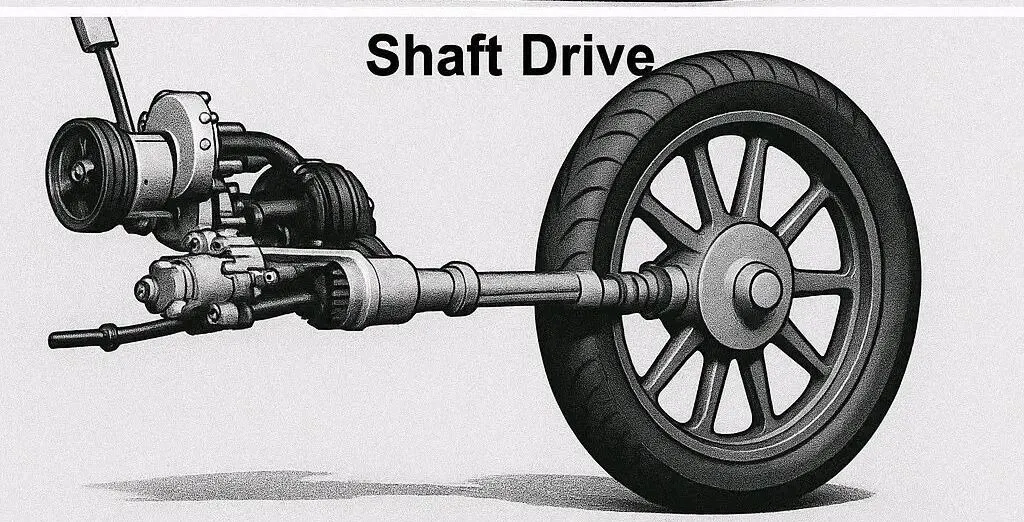

Shaft Drive

A completely enclosed shaft (with universal joints or gears) transfers power from the transmission to the rear wheel. Used in many touring bikes, large cruisers, and high-end motorcycles for reliability and low maintenance.

Why riders like it:

- sealed system, unaffected by dirt, rain, mud

- nearly maintenance-free, no lubrication, no tension adjustments

- very smooth and reliable on long tours

Maintenance needed:

- periodic final-drive oil change (gearbox fluid)

- seal checks, rarely, but possible

alignment and universal joint inspection (mostly on shaft-suspension bikes).

Pros & Cons: Which Drive Fits What Riding Style?

| Riding Style / Requirement | Best Drive Type | Why |

|---|---|---|

| Long-distance touring, bad-road conditions, heavy use, and weather exposure | Chain Drive | Frequent RPM changes, customization, sprocket tuning, sport/performance riding |

| Commuting, low maintenance, quiet city/cruiser riding | Belt Drive | Silent, smooth, no-lube; low-maintenance and clean |

| Long-distance touring, bad-road conditions, heavy use, weather exposure | Shaft Drive | Enclosed system. Protected from weather/dirt; durable; ride longer with minimal upkeep |

| Mixed use: occasional touring + city commuting | Chain or Belt, depending on willingness to maintain | Enclosed shaft resists contamination; the chain needs frequent clean/maintenance |

| Harsh weather, mud, sand, rain, off-road hybrids | Shaft Drive (or clean-chain setup) | Enclosed shaft resists contamination; the chain needs frequent cleaning/maintenance |

There’s no one-size-fits-all. The best is what suits your ride + riding style.

How to Maintain Each Motorcycle Transmission Type? (And Avoid Roadside Failure)

Chain Drive: The Rider-Dependent Workhorse

- Chain cleaning & lubrication: Regularly (every 500-700 km or after wet/rain rides). Clean old grease, remove grit, and apply fresh chain lube. This extends chain & sprocket life significantly.

- Chain tension check: Every few rides, slack changes with wear and temperature. Too loose = chain slap; too tight = bearing stress.

- Sprocket teeth inspection: Look for hooked or worn teeth (shark-fin shape), replacement before chain or sprocket failure.

- Sprocket & chain replaced as a set: Replacing the chain alone on worn sprockets causes premature wear and risk of failure. Always replace together.

- Avoid cheap parts: Low-quality chains & sprockets wear faster, stretch irregularly, and lead to more maintenance.

If you ride long distances, carry a load, or frequently ride in wet/dusty areas, neglecting chain maintenance always leads to a breakdown. Chain drive demands rider discipline, but rewards with flexibility and power.

Belt Drive: Low Maintenance but Needs Monitoring

- Check belt tension: Over time and temperature cycles cause slack or stretch. Maintain exact manufacturer spec.

- Inspect for cracks or belt wear: Rubber belts age, especially under heat or harsh conditions. Replace as soon as cracks or fraying appear.

- Pulley alignment check: Misaligned pulleys wear belt edges unevenly, leading to premature failure.

- Keep the rear wheel clean of debris: Belt drive belts don’t like stones or sharp impacts — such debris can tear belts.

For riders who value a quiet ride and minimal maintenance, a belt drive offers comfort and simplicity. If maintained properly, a belt can easily last tens of thousands of km.

Shaft Drive: Set It and (Mostly) Forget It

- Final drive oil change: Typically every 12,000–20,000 km or as per the manufacturer. Old oil degrades lubrication.

- Seal and joint inspection: Even sealed systems can suffer from wear. Check seals, joints, and the presence of leaks or metal shavings.

- Universal joint / shaft-suspension linkage check: On bikes with shaft-suspension or swingarms, check bearings and linkage regularly. Any wear or looseness affects stability.

- Avoid heavy load + aggressive riding patterns without checks: Especially on long tours, heat and heavy load cause drivetrain stress.

The shaft drive’s strength is reliability. For touring riders, daily commuters, and long-haul riders, it offers peace of mind. But it still demands periodic fluid maintenance. Don’t ignore it

Perfect Drives Are All About Choices

Chain, belt, and shaft drives each bring trade-offs. None is universally superior. What matters most is your ride style, maintenance habits, and expectations.

A well-maintained chain drive delivers power, flexibility, and affordability. Perfect for tuners, sport riders, and DIYers.

A belt drive delivers quiet, low maintenance, and cleanliness. Ideal for cruisers, commuters, and comfort-oriented riders.

A shaft drive delivers reliability, weather resistance, and minimal routine maintenance. Perfect for tourers, long-haul riders, and those who value peace of mind over tinkering. Maintain what you ride. Respect what’s under your wheel.